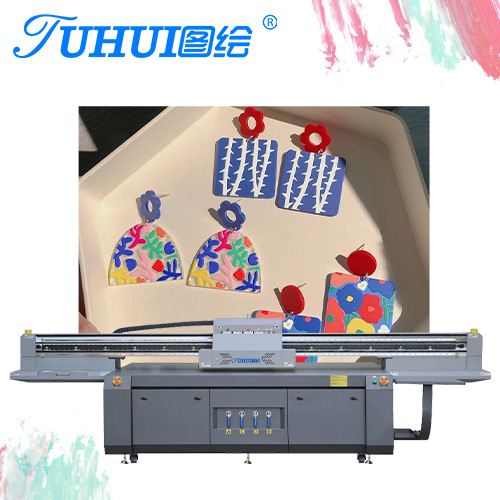

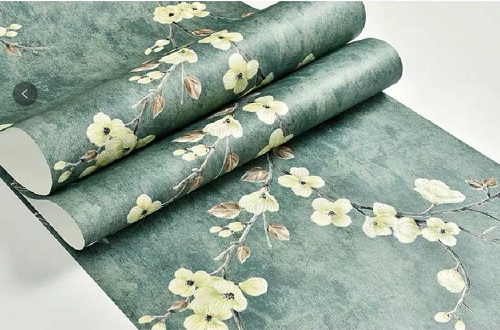

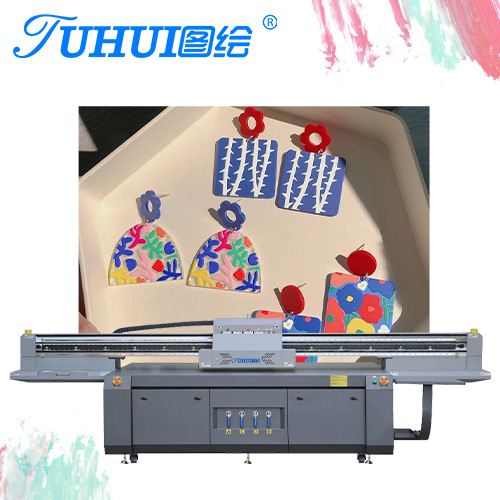

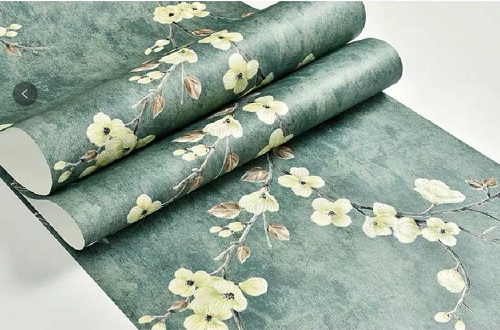

With the increasing popularity of UV curing technology in the printing industry, UV printers have been paid attention to by more and more printing companies. UV printers utilize ultraviolet light for instant curing of the inks. They produce prints that are ready to handle immediately after they are printed – no drying time, no need for overlaminates to prevent smudging. As a relatively young digital ink-jet printing equipment, UV flatbed printers have been the most attractive machine in social production in recent years. There are many kinds of UV printers, one of the most popular one is the UV flatbed printers. The design and manufacturing purpose of the UV flatbed printer was mainly used for the printing of hard materials. It broke through the limitation of ink-jet technology that can only be printed on soft materials. It can be applied to glass, PVC acrylic, integrated wallboard, ceramic tiles, etc. Material, so it is also called a “universal printer”.  So why are UV flatbed printers so popular? According to our researches, it is probably attributed to its benefits. We have inquired about some of the users of the UV printers and summarized the following benefits of the UV flatbed printers.

So why are UV flatbed printers so popular? According to our researches, it is probably attributed to its benefits. We have inquired about some of the users of the UV printers and summarized the following benefits of the UV flatbed printers.

The machines use eco-friendly techniques.

Conventional printing techniques contain the use of inks that have special solvents that evaporate into the air upon spraying onto a material, and once the solvents have fully evaporated the ink dries up living a digital image. Unlike solvent ink, UV flatbed printers are much more environmental-friendly because eco-friendly printing needs no volatile organic compounds.

The printers promise higher efficiency.

It promises higher efficiency and faster production speeds because fewer workers are required. The machine-driven working process will also enable mass production in a shorter time.

It is also a universal printer that costs less.

The UV printer will also help to save wall printing price because there’s often no need to use additional materials in finishing or mounting and additional protection. By printing directly to the substrate, UV printers end up using fewer materials, which can save customers time and expense.

The printing products are consistent & of high quality.

By using a UV flatbed printer, consistent and accurate prints are achieved at a faster rate. The ink cures or solidifies in only a few seconds and a great number of images can be printed in a shorter time. The fast curing of the ink also minimizes the risk of ink distortion before drying generating consistent and accurate images.

So how does a UV flatbed printer work? Here we take the example of UV printer for phone cases.

Step 1: The design of the 3D image

First of all, you are required to design a 3D file of the phone case you want to print. Through CAD software, you can easily make a 3D image. Or with a 3D scanner, or downloaded from an online marketplace. The image can be of any type and the UV printer will help to print it on the proper material. Once the 3D image is prepared, you can proceed to print it and prepare the second step.

Step 2: The printing process

The second step is the actual printing process. During the process, you need to choose which material will best suit the specific properties required for your phone case. Most of these materials help you to achieve the precise design result and some others. The moment the ink hits the surface it is exposed to high levels of UV light causing the ink to cure instantly. The ink cannot be absorbed by the materials or distorted before it dries, UV printing can be used comfortably on a wide range of substrates: fabric, canvas, glass, plastic, wood, coated media, Polystyrene, PVC, acrylic, wood, and aluminum and many more. Because the UV ink is more resistant to agents of corrosion, the images are long-lasting and more consistent. This makes UV printing more suitable for banner printing, pamphlets, billboards, flyers, promotional clothing, etc.

Step 3: The Final Step of the Printing Process

The third step is the finishing process. This step requires specific skills and materials. When the object is finished, often it cannot be directly used or delivered until it has been sanded, lacquered, or painted. When the final process is finished, you may surprise at the art you create.

UV printer’s price and future development

UV printer’s price is pretty higher than other printers mainly for its multi-functions and the after-sales services that the printer manufacturers offer. But we should believe that with the development of UV LED technology, the price of the printer will gradually become affordable to most people. The UV printing industry strives to update its hardware, materials, and process to create objects or parts. Depending on many factors such as budget, design, or function, choosing the appropriate UV printing process and the proper material is essential. UV printing can create many different printed objects that were previously only fabricated through mass manufacturing methods. The prospect of the printer will provide opportunities for many entrepreneurs.