Introduction

Several years ago, countries with developed ceramic industries such as Spain and Italy introduced inkjet ceramic tile printing technology, but inkjet printing technology started late. In the past two years, many ceramic companies have gradually introduced inkjet technology, and the continued hot sale of inkjet tiles has attracted more and more people to join. Then it led a wave of inkjet craze in the market, and products such as inkjet porcelain plate paintings and inkjet wood-grain tiles swept

Details

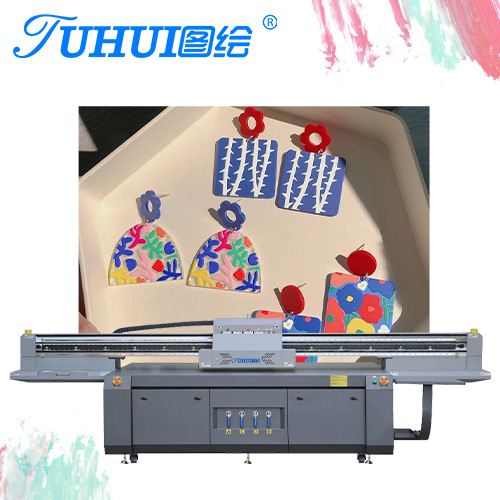

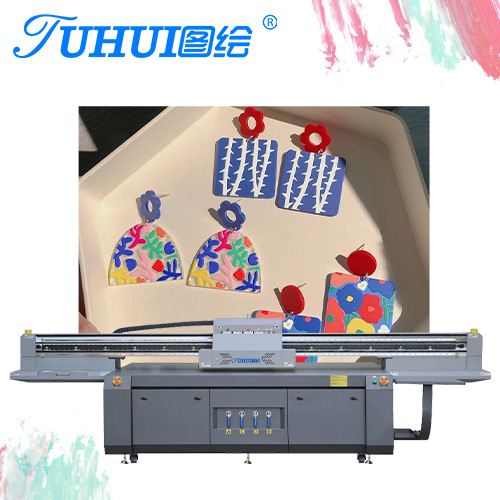

Inkjet printer technology-the third revolution of ceramic printingBefore the advent of inkjet printing technology, ceramic tile designs generally used screen printing and roller printing technologies. The first-generation screen printing technology was a flat printing and could not achieve the uneven surface printing of tiles, so it was difficult to use it. The surface of the ceramic tile achieves the multi-dimensional and three-dimensional effect of the surface. Compared with screen printing, the breakthrough of roller printing is that it can realize the printing of concave and convex surfaces, so that the surface layer of the brick is richer and the simulation degree of nature is higher. The third-generation inkjet printer technology breaks through the limitations of traditional printing technology and can print effects that the first two technologies cannot print. TUHUI understands that the working principle of inkjet printing technology is similar to that of inkjet printers. What kind of pattern can be printed by inputting any pattern. It can be said that the emergence of inkjet printing technology has transformed ceramic tile production from "copiers" to "printers". And the pattern of tiles has never been able to do anything from then on. It is understood that the TUHUI brand that introduced ceramic tile inkjet printer technology early in China, using the Italian Kerajet digital inkjet printing system, took the lead in launching digital products and became the first domestic enterprise to "eat crabs". Subsequently, it also launched a high-end ceramic flatbed printer series integrating roller printing and spray printing, and launched a mid-end series of flatbed flatbed printer products produced by the German-Italian cooperation technology INK-CID digital inkjet printing system. TUHUI became the first ceramic tile flatbed printer manufacturer in Guangdong to enter the field of inkjet printing. Then the ceramic industry immediately set off an innovative trend of ceramic tile designs. Inkjet tile printers make home decoration more personalized.The application of inkjet technology to the field of ceramics can be regarded as a major revolution in the ceramic industry. Inkjet technology can not only draw any pattern on the surface of a flat tile, but also draw any pictures on the uneven and uneven surface, so that the pattern and expression of the tile can be changed. Enriched instantly. With the popularity of inkjet technology, products such as wood grain bricks and imitation stone bricks can be made more and more realistic, and then become the new favorites on the market. In internationally renowned ceramic exhibitions such as Italy and Spain, inkjet printing technology has also set off an innovative trend of ceramic tile designs in the industry.Simply put, inkjet technology can print any pattern on the tiles-landscape photos, world famous paintings, family portraits, wedding photos and everything you can imagine. Putting the tiles with these patterns in the picture frame is a famous painting that will not corrode and fade. If these patterns are printed on large-size tiles, as a background wall, it also has infinite style and personality.

It is understood that the TUHUI brand that introduced ceramic tile inkjet printer technology early in China, using the Italian Kerajet digital inkjet printing system, took the lead in launching digital products and became the first domestic enterprise to "eat crabs". Subsequently, it also launched a high-end ceramic flatbed printer series integrating roller printing and spray printing, and launched a mid-end series of flatbed flatbed printer products produced by the German-Italian cooperation technology INK-CID digital inkjet printing system. TUHUI became the first ceramic tile flatbed printer manufacturer in Guangdong to enter the field of inkjet printing. Then the ceramic industry immediately set off an innovative trend of ceramic tile designs. Inkjet tile printers make home decoration more personalized.The application of inkjet technology to the field of ceramics can be regarded as a major revolution in the ceramic industry. Inkjet technology can not only draw any pattern on the surface of a flat tile, but also draw any pictures on the uneven and uneven surface, so that the pattern and expression of the tile can be changed. Enriched instantly. With the popularity of inkjet technology, products such as wood grain bricks and imitation stone bricks can be made more and more realistic, and then become the new favorites on the market. In internationally renowned ceramic exhibitions such as Italy and Spain, inkjet printing technology has also set off an innovative trend of ceramic tile designs in the industry.Simply put, inkjet technology can print any pattern on the tiles-landscape photos, world famous paintings, family portraits, wedding photos and everything you can imagine. Putting the tiles with these patterns in the picture frame is a famous painting that will not corrode and fade. If these patterns are printed on large-size tiles, as a background wall, it also has infinite style and personality. TUHUI learned that Mona Lisa Ceramics was the first in the industry to propose "porcelain art paintings" produced by inkjet technology, and it was well received by the industry. Ink technology can keep the artwork on the tiles for a long time. The world famous inkjet porcelain plate paintings launched by Malaz is also an attempt to personalize ceramic tiles. In addition, the inkjet microcrystalline stones of Mati Ceramics, the inkjet wood-grain tiles of Jinyi Tao and Kangtuo are amazing. Ink technology can perfectly express the value of personalized appreciation. Inkjet tile personalized customization has not become a climateInkjet tile printers are a major trend in the industry and have attracted the attention of many individual consumers. However, industry insiders believe that inkjet tile flatbed printers still have a long way to go.In the current situation of serious homogeneity of ceramic flatbed printer products and insufficient personalized products, ceramic flatbed printers can be said to bring a fresh breath to the same products. However, the personalized production of inkjet tiles has not yet been popularized, and the high cost and difficulty in mass production have become major problems. TUHUI understands that the investment cost of inkjet ceramic tile printer equipment is very high. There are tens of thousands of ceramic tile inkjet printers that every enterprise can afford, and ink and glaze with inkjet technology also require high costs. . In addition, because personalized inkjet tiles are different from the mass production of general tiles, this also hinders the possibility of mass promotion of inkjet tiles from an operational perspective.

TUHUI learned that Mona Lisa Ceramics was the first in the industry to propose "porcelain art paintings" produced by inkjet technology, and it was well received by the industry. Ink technology can keep the artwork on the tiles for a long time. The world famous inkjet porcelain plate paintings launched by Malaz is also an attempt to personalize ceramic tiles. In addition, the inkjet microcrystalline stones of Mati Ceramics, the inkjet wood-grain tiles of Jinyi Tao and Kangtuo are amazing. Ink technology can perfectly express the value of personalized appreciation. Inkjet tile personalized customization has not become a climateInkjet tile printers are a major trend in the industry and have attracted the attention of many individual consumers. However, industry insiders believe that inkjet tile flatbed printers still have a long way to go.In the current situation of serious homogeneity of ceramic flatbed printer products and insufficient personalized products, ceramic flatbed printers can be said to bring a fresh breath to the same products. However, the personalized production of inkjet tiles has not yet been popularized, and the high cost and difficulty in mass production have become major problems. TUHUI understands that the investment cost of inkjet ceramic tile printer equipment is very high. There are tens of thousands of ceramic tile inkjet printers that every enterprise can afford, and ink and glaze with inkjet technology also require high costs. . In addition, because personalized inkjet tiles are different from the mass production of general tiles, this also hinders the possibility of mass promotion of inkjet tiles from an operational perspective. According to industry insiders, the emergence of ceramic tile inkjet printing technology can meet the individual needs of designers to a greater extent. Whether European style, Chinese style or other styles can be implemented on ceramic tile products, it can also be customized according to customers. Request, print out personal photos or favorite famous paintings. In terms of the characteristics of consumer demand, consumption levels continue to increase, and the demand for personalized products will also increase. This is a very large and potential market. However, whether it is mass production or customization, the focus is on the production level. How to successfully realize the sales and promotion of personalized products requires product design, product matching, market channel development, and supporting marketing methods to adapt to it.Due to various reasons, the market acceptance of inkjet tile printers is not high, and its advantages have not yet been fully demonstrated. However, when it comes to the future of inkjet tile printers, people in the industry still hold high hopes. The extensive cooperation between personalized inkjet printer products and designers will become a trend. Designers like individuality, and inkjet can show various effects better. The customized production of ceramic tile products still needs the solution of many problems such as the clarification of channels and the accuracy of market positioning.

According to industry insiders, the emergence of ceramic tile inkjet printing technology can meet the individual needs of designers to a greater extent. Whether European style, Chinese style or other styles can be implemented on ceramic tile products, it can also be customized according to customers. Request, print out personal photos or favorite famous paintings. In terms of the characteristics of consumer demand, consumption levels continue to increase, and the demand for personalized products will also increase. This is a very large and potential market. However, whether it is mass production or customization, the focus is on the production level. How to successfully realize the sales and promotion of personalized products requires product design, product matching, market channel development, and supporting marketing methods to adapt to it.Due to various reasons, the market acceptance of inkjet tile printers is not high, and its advantages have not yet been fully demonstrated. However, when it comes to the future of inkjet tile printers, people in the industry still hold high hopes. The extensive cooperation between personalized inkjet printer products and designers will become a trend. Designers like individuality, and inkjet can show various effects better. The customized production of ceramic tile products still needs the solution of many problems such as the clarification of channels and the accuracy of market positioning.